The first Printed Solar Panels were demonstrated in Pacprint 17 trade show at Melbourne from May 23-26, 2017. Printed Solar Panels are combination of multiple layers of printing of silicon electrodes with Flexo & Screen Printing process, layering electrodes, slot die coating the strips for opacity and so on. To put it simply, it is a five step process –

- Metallic “wires” are printed from silver ink onto transparent plastic film.

- Transparent blue electrodes are coated on top of the silver wires. Together these form

the positive (+) electrodes of the Solar Panel. - The red “active layer” stripes are coated. This material is a non-toxic polymer that

absorbs light and converts it into electricity. - A thin aluminum layer is deposited using a Roll2Roll sputter coater, to form

the negative (-) electrodes of the Solar Panel. - Finally, a plastic film is then applied (Laminated) to protect the cells from damage, and wires are attached.

And the Solar Panels are ready to use. Looks simple huh! This is the outcome of two decades of research on solar cells by professors in the University of Newcastle, Australia. Department of Physics, Chemistry, Electrical, Mechanical engineering AND Economists collaborated to create this New Direction which will have an impact on planet Earth. Three professors and about 25 students of University of Newcastle are working full time on the project. Undergraduate students are exposed regularly to the ongoing research. The product is created on Flexo press and other equipment in-house.

Printed Solar panels developed by University of Newcastle, Australia, mounted on tents were illuminated in evening with the solar power generated from these panels during Pacprint17, Melbourne.

New Direction is the Only Direction

In past one decade print industry globally is focused on innovative solutions for optimization, reducing wastage and automation. To grow and stay in business diversification from offset to digital and large format is necessary. There are innovations in Print Industry like Digital Coatings, Laser Die cutting, 3d Printing, box and bag manufacturing. Despite all these innovations, print is accomplishing one task – “absorbing the light on substrate and giving a message” in form of books, posters, folding cartons, boxes, signage…………Printed Solar Panels in real sense is setting new direction in Print by going beyond giving message and enabling printers to create products that will be of great use to the entire world and save environment.

COSTS & EFFICIENCY: As of today (May 2017), the cost of producing the Printed Solar Panels is Australian Dollar 30 per square meter. Professor Paul Dastoor of University of Newcastle is expecting this to be in single digit in actual production as the sourcing of raw material and production will be at large scale. A square meter of printed solar panel generates 25 Watt of power. The life of Solar Panel is 3 to 5 years. Well, it is a quarter of conventional Solar Panels available today. However, the initial costs are going to be much less. Further because of flexibility (0.2mm thick versus solar panels available today at 2.5 mm thick) they can be mounted on any surface like walls and automobiles and windows. They are also easily replaceable or portable.

It will be interesting to see this technology available for practical application, which Newcastle University expects by the end of 2017.

Revolutionary Innovation

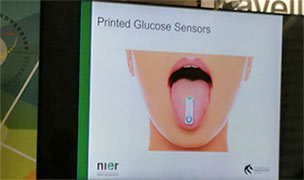

Application of Printed Glucose Sensor

University of Newcastle is not resting on accomplishment of Printed Solar Panels. Their research team is close to inventing Printed Glucose Sensors for stabilizing glucose levels in people with diabetes. This will eliminate taking pills and stabbing each day with insulin shots. We leave it to you to imagine the role of print in future when this is successful.

Well Done University of Newcastle, Australia.