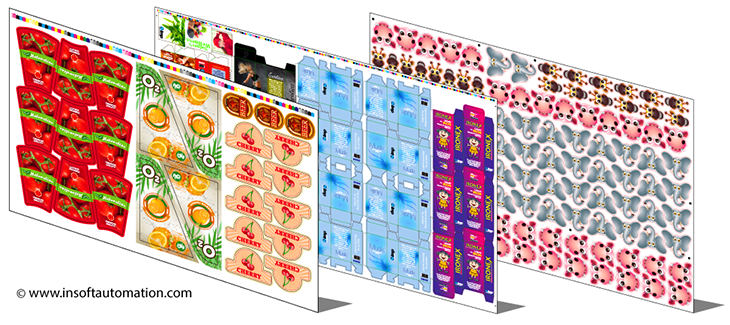

Optimum arrangement of 2D shapes on a larger rectangular plane is a very old challenge. In fact, it is not a problem unique to printing industry. Any industry that must cut smaller shapes out of larger flat have to tackle this optimization problem. Examples are sheet metal, glass, wood, cloth & leather industries to name a few. But this problem takes on a completely new dimension and complexity in printing industry.

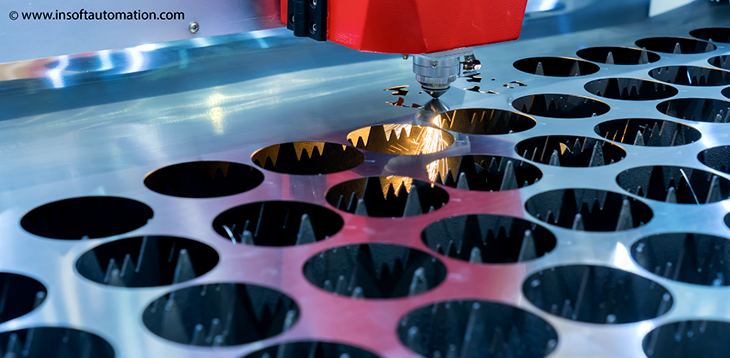

Paper is probably the most malleable and easily workable flat substrate. One can fold, crease, emboss, coat, varnish, paste, die cut, CNC cut, guillotine cut a paper while a sheet metal can only be CNC cut, bent, welded, and painted. Essentially, the finishing operations are way too many in our printing industry and a ganging software or an imposition software that does not consider the requirements and constraints of the finishing operations would be no good.

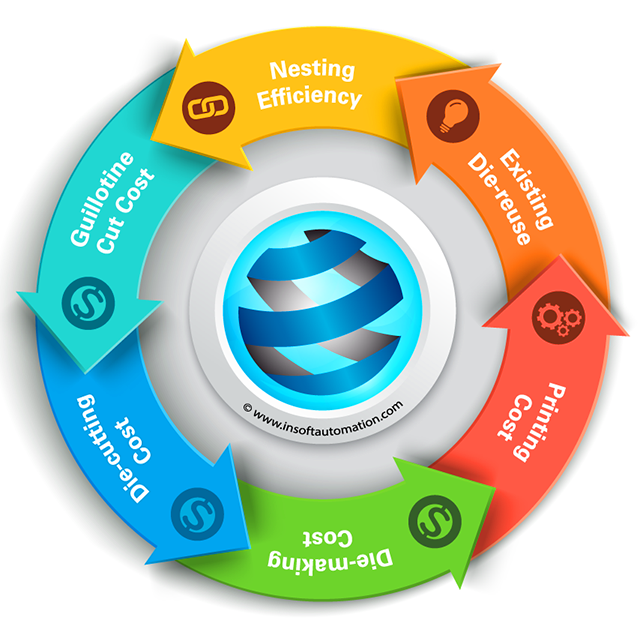

Another important fact (and in my humble opinion, the most important one) that differentiates ganging from simple nesting is the fixed cost component of each imposition layout. In the offset printing scenario, when optimizing for paper utilization, it will be a grave mistake to ignore the cost of making the plates and press make-ready. The challenge is not just about paper utilization but also about press time utilization. It is about balancing the two and finishing process as well.

In a simple nesting problem, the pieces that go on the sheet/roll and their required quantity is already known. Subsequently, what remains to be solved is to find a compact way to arrange them on the sheet. It is not that simple when ganging hundreds of jobs across multiple presses and finishing equipment. The problem definition is much looser, the unknown variables are more, and constraints are also more. A lot many decisions must be made by the software before it reaches the level of simple nesting. The software must choose-

- Which set of jobs to place together?

- How many copies of each job on a single imposition, so that over-runs are minimized?

- The right press/technology. Offset vs Digital?

The software must also ensure the compatibility of the selected sheet size or press with the required finishing operations. It is not necessary that a sheet that can be printed, can also be cut. It depends on the sheet sizes that the finishing equipment can handle.

There is much more to the ganging problem than minimizing wastage of paper. Without solving all these puzzles, you will have an impractical solution that will require too many human inputs, defeating the purpose of having an automatic ganging solution.

Santosh Mulay

Email: santosh@insoftautomation.com

bit.ly/3f97gbf